What is Polyethylene Plastic? - AirX Carbon

What is polyethylene plastic?

What is polyethylene plastic?

If you're wondering, "What is Polyethylene Plastic," we've got you covered

In this article, we will delve into the depths of this versatile material, exploring its composition, properties, and wide-ranging applications. Join us as we unravel the mysteries of polyethylene plastic and discover how AirX Carbon is revolutionizing the industry with sustainable biobased polyethylene plastics solutions. Get ready to expand your knowledge and embark on a journey to understand the incredible potential of polyethylene plastic in shaping a greener future. Besides, understanding "What is Polyethylene Plastic" becomes even more critical with the advancements made in Bio Polyethylene, which harnesses renewable resources for its production.

1. What is polyethylene plastic?

Polyethylene plastic is a type of polymer that is widely used in various industries and everyday products. It belongs to the family of polyolefins and is derived from ethylene, a hydrocarbon gas obtained from natural gas or crude oil.

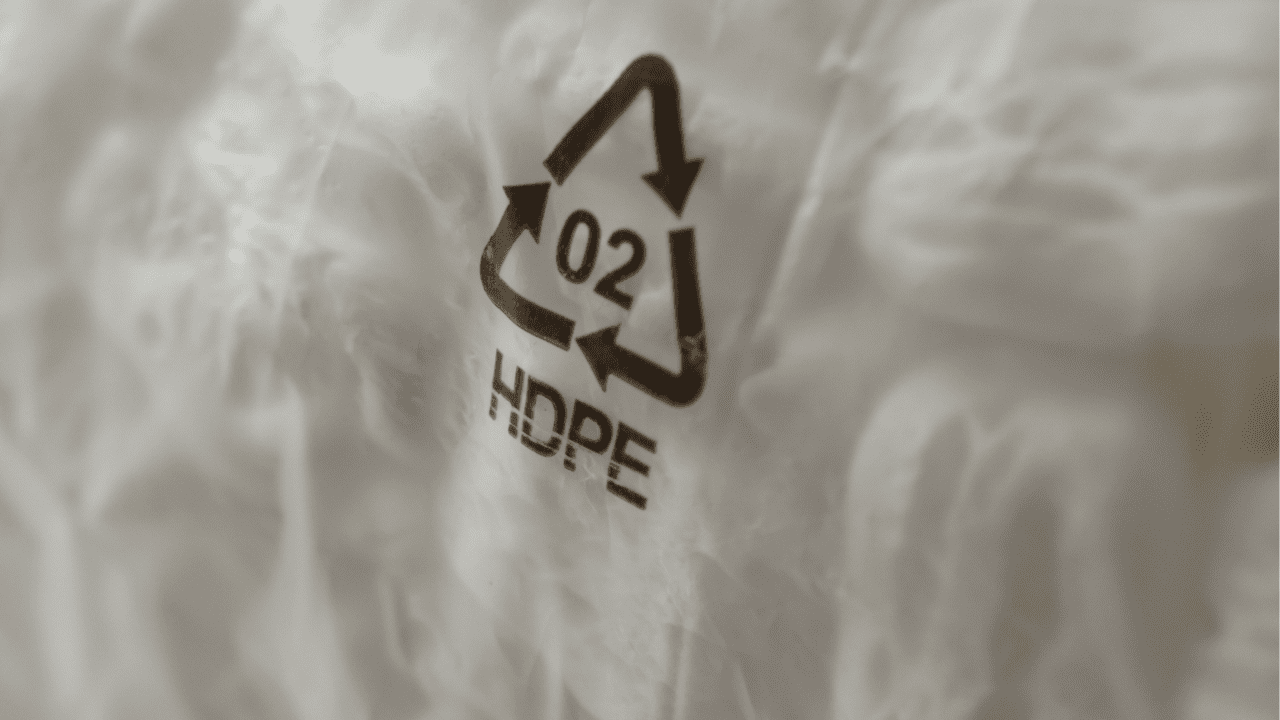

Polyethylene is known for its versatility, durability, and excellent resistance to moisture, chemicals, and impact. It can be manufactured in different forms, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), each with unique properties and applications.

HDPE, characterized by its high strength-to-density ratio, is commonly used for rigid containers, pipes, and industrial applications. On the other hand, LDPE, with its flexibility and toughness, is utilized for packaging materials, plastic bags, and squeeze bottles. "What is Polyethylene Plastic" is a crucial inquiry for eco-conscious consumers as its recyclable nature significantly contributes to sustainability efforts.

2. Applications of Polyethylene plastic

Inquiring about "What is Polyethylene Plastic" leads to the discovery of its various grades, each tailored to specific applications and industries

HDPE

HDPE Plastic

HDPE (high-density polyethylene) plastics have a wide range of applications across different industries due to their excellent physical properties and chemical resistance. Some common applications of HDPE plastics include:

Packaging: When discussing packaging solutions, "What is Polyethylene Plastic" emerges as a prominent choice due to its exceptional strength and flexibility. HDPE is widely used for packaging purposes, including bottles, containers, caps, and lids. Its durability and resistance to chemicals make it suitable for storing various products such as cleaning agents, detergents, cosmetics, and food items.

Construction: HDPE is commonly used in the construction industry for applications such as geomembranes, geotextiles, and drainage systems. Its strength, resistance to chemicals, and UV stability make it suitable for lining landfills, ponds, and reservoirs, as well as for erosion control and waterproofing applications.

Automotive Components: HDPE is utilized in various automotive components, including fuel tanks, bumpers, door panels, and interior trim. Its lightweight nature, impact resistance, and ability to withstand extreme temperatures make it ideal for these applications.

Industrial Containers: HDPE is preferred for industrial containers such as drums, barrels, and intermediate bulk containers (IBCs). These containers are used for storing and transporting chemicals, lubricants, hazardous materials, and other industrial liquids due to HDPE's chemical resistance and durability.

Agricultural Applications: HDPE is utilized in agricultural applications, including agricultural pipes for irrigation systems, greenhouse films, and mulch films. Its resistance to chemicals, UV stability, and durability make it ideal for protecting crops and optimizing agricultural processes.

Considering these diverse applications, "What is Polyethylene Plastic" remains a pivotal topic in both industrial and environmental discussions.

LDPE

LDPE Plastics

LDPE (low-density polyethylene) plastics are known for their flexibility, toughness, and excellent moisture barrier properties. They find applications in various industries due to their unique characteristics. Some common applications ofLDPEplastics include:

Packaging Films: LDPE is extensively used for producing flexible packaging films, including plastic bags, shrink wraps, and stretch films. Its ability to conform to different shapes, moisture resistance, and sealability make it suitable for packaging products ranging from food items to industrial goods.

Coatings: LDPE is used as a coating material for paper and cardboard products, providing moisture resistance, heat-sealing capabilities, and enhancing durability. It is often used in applications such as disposable cups, milk cartons, and frozen food packaging.

Agricultural Films: LDPE is used in agricultural applications, particularly for manufacturing mulch films and greenhouse covers. These films help control weed growth, conserve moisture, regulate temperature, and protect crops from pests and weather conditions.

Medical and Healthcare Products: LDPE finds applications in the medical field for items such as disposable gloves, medical packaging films, and tubing. Its flexibility, low toxicity, and ability to be sterilized make it suitable for these applications.

Household Products: LDPE is found in various household products such as trash bags, food storage containers, and squeeze bottles for household cleaners. Its flexibility, ease of use, and moisture resistance make it suitable for these everyday applications.

From food packaging to wire insulation, "What is Polyethylene Plastic" encompasses a wide array of applications for both HDPE and LDPE, making them essential polymers in various industries.

3. The innovations of Bio Polyethylene plastic?

The environmental impact of polyethylene plastic raises essential questions about "What is Polyethylene Plastic" and the need for sustainable alternatives.

Bio polyethylene plastic refers to a variant of polyethylene that is derived from renewable resources, such as sugarcane ethanol or other biomass sources, instead of fossil fuels. In another way, bio polyethylene can be the combination of recycled PP/PE and raw materials derived from renewable sources, and offers several unique benefits such as: sustainable packaging, consumer goods and industrial applications.

AirX Bio polyethylene made from coffee grounds combined with traditional PP/PE to create bio polyethylene plastic.

AirX Bio polyethylene made from coffee grounds

In our bio polyethylene plastic, the coffee waste serves as a filler or reinforcement, imparting extra strength and desirable properties. Comprising 70% of the mixture, the coffee grounds greatly enhance the biodegradability of our composite.

By combining "What is Polyethylene Plastic" with the strides made in Bio Polyethylene, we foster a deeper appreciation for sustainable practices and the potential to create a circular economy for plastics.

>>>Discover AirX bio polyethylene plastic made from coffee grounds

Special properties of bio polyethylene plastic

Environmental Sustainability: AirX bio polyethylene plastic is derived from renewable sources - coffee grounds, rather than fossil fuels. By reducing reliance on non-renewable resources, it helps mitigate carbon emissions and decreases the environmental impact associated with traditional plastic production. The use of renewable feedstocks contributes to a more sustainable and circular economy.

Biodegradability: One of the advantages of AirX bio polyethylene plastic is its biodegradability. It is designed to break down naturally and degrade over time, significantly reducing its persistence in the environment. This characteristic makes it a valuable solution for reducing plastic waste and minimizing the ecological footprint associated with plastic disposal.

Performance and Versatility: Despite its sustainable properties, AirX bio polyethylene plastic does not compromise on performance and versatility. It offers similar functionality, durability, and flexibility as traditional polyethylene plastic. This allows for a wide range of applications across industries, ensuring that sustainable materials can be seamlessly integrated into existing

As we delve deeper into "What is Polyethylene Plastic" of the bio-based variety, it becomes evident that the material exhibits comparable mechanical properties to its fossil fuel-derived counterpart. This similarity ensures that industries and manufacturers can transition to bio polyethylene plastics without compromising on product performance or functionality.

In conclusion, understanding "What is Polyethylene Plastic" extends beyond the realm of traditional petroleum-based plastics, as bio polyethylene emerges as a sustainable and promising solution. By embracing bio-based alternatives, we can make strides towards reducing our reliance on non-renewable resources, curbing greenhouse gas emissions, and creating a more environmentally responsible future.

Contact us

AirX is the world’s first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!