Product Carbon Footprint: Strategies for Sustainable Manufacturing

In today's world, the environmental impact of manufacturing processes and products is of paramount importance. Understanding and addressing the product carbon footprint is crucial for businesses striving to achieve sustainability goals.

In this article, we will explore factors affecting product carbon footprint. By improving these factors, businesses can not only contribute to a greener future but also gain a competitive edge in an increasingly environmentally conscious market. Join us as we delve into the world of sustainable manufacturing and uncover innovative solutions to minimize the product carbon footprint.

Definition of product carbon footprint

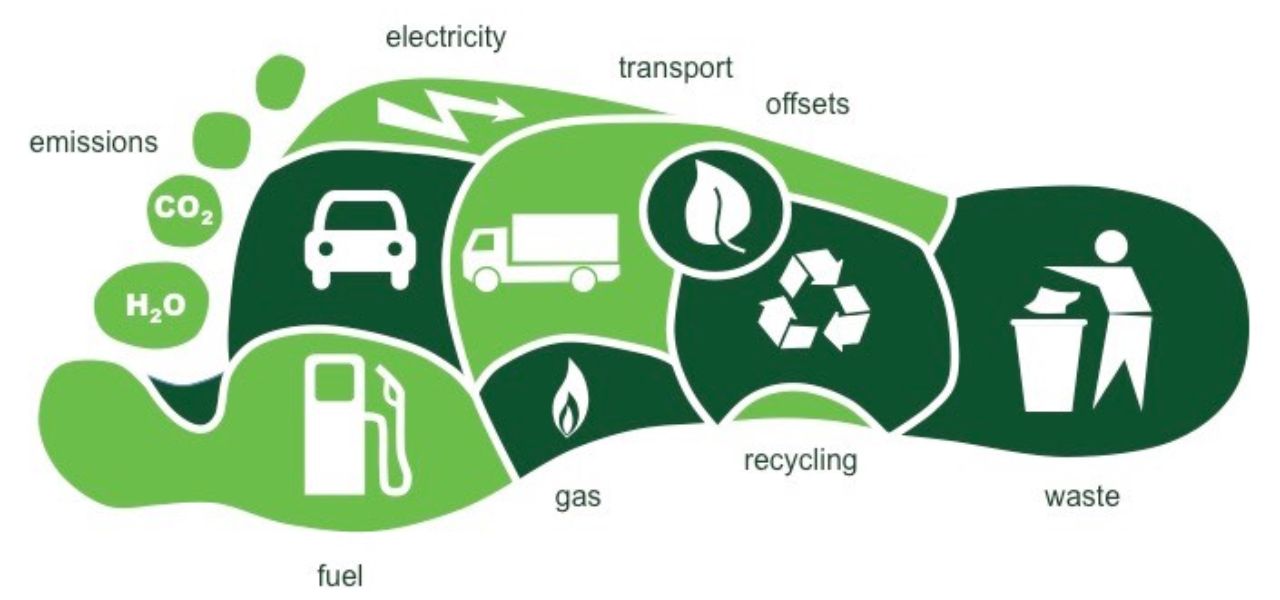

The product carbon footprint is a crucial metric used to measure the total greenhouse gas emissions generated throughout the life cycle of a product, from its raw material extraction to its disposal. It quantifies the environmental impact associated with the production, distribution, use, and disposal of a specific product. Understanding and addressing the carbon footprint of products is essential for businesses aiming to minimize their environmental impact and promote sustainability.

The calculation of a product carbon footprint involves assessing various factors, including the energy consumed during manufacturing, transportation, and distribution processes, as well as the emissions released during raw material extraction and waste disposal. It takes into account both direct emissions, such as those from burning fossil fuels, and indirect emissions resulting from purchased electricity or the extraction and production of raw materials.

By determining the product carbon footprint, businesses gain insights into the environmental impact of their products and can identify opportunities to reduce emissions. This information allows companies to make informed decisions in product design, sourcing of materials, manufacturing processes, and transportation methods, among others. By implementing strategies to lower carbon footprint, businesses can contribute to climate change mitigation efforts and promote sustainable consumption and production practices.

Reducing the product carbon footprint involves adopting sustainable manufacturing practices, utilizing renewable energy sources, optimizing supply chains, and improving energy efficiency. It also entails promoting the use of eco-friendly materials, embracing circular economy principles, and implementing effective waste management strategies. By implementing these measures, businesses can not only reduce their environmental impact but also enhance their brand reputation, attract eco-conscious consumers, and achieve long-term cost savings.

In conclusion, the product carbon footprint is a vital concept in sustainability and environmental responsibility. By measuring and addressing the environmental impact associated with the production and use of their products, businesses can take proactive steps toward reducing their carbon emissions and fostering sustainable manufacturing practices. Through these efforts, they contribute to the global goal of mitigating climate change and building a more sustainable future.

Factors Affecting Product Carbon Footprint

The product carbon footprint refers to the total greenhouse gas emissions produced during the life cycle of a product, including its manufacturing, transportation, use, and disposal. Understanding the factors that influence the carbon footprint of product is crucial for companies seeking to reduce their environmental impact and embrace sustainability.

Raw Material Selection:

The choice of raw materials plays a significant role in determining the product carbon footprint. Opting for sustainable alternatives, such as plant-based plastic, can have a positive impact. Unlike traditional plastic derived from fossil fuels, plant-based plastic is made from renewable sources like coffee, corn or sugarcane. The carbon footprint of plant-based plastic is lower because these plants absorb carbon dioxide during their growth, effectively reducing the net carbon emissions associated with the material.

Energy Consumption and Efficiency:

The energy used in manufacturing processes contributes to the product carbon footprint. By adopting energy-efficient technologies and practices, companies can reduce their energy consumption and associated greenhouse gas emissions. This can include investing in energy-efficient machinery, optimizing production processes, and utilizing renewable energy sources like solar or wind power.

Manufacturing Processes:

The methods and techniques employed during manufacturing can have a significant impact on the product carbon footprint. Implementing lean manufacturing principles and process optimization can help minimize waste, reduce energy consumption, and lower emissions. For example, utilizing closed-loop manufacturing systems that recycle and reuse materials can significantly reduce the carbon footprint of products.

Supply Chain Management:

The carbon footprint extends beyond the boundaries of a company's own operations. Factors such as transportation, logistics, and supplier practices can contribute to the overall product carbon footprint. Companies can work towards reducing emissions by optimizing their supply chain, choosing eco-friendly transportation options, and collaborating with suppliers who prioritize sustainability.

By considering these factors and making conscious decisions throughout the product life cycle, companies can effectively reduce the product carbon footprint. The use of plant-based plastic as a sustainable alternative material is an excellent example of how businesses can make environmentally conscious choices, as it offers a lower carbon footprint compared to traditional plastic. By integrating these practices, companies can not only reduce their environmental impact but also enhance their brand reputation and contribute to a greener future.

Benefits of Sustainable Manufacturing

Sustainable manufacturing offers numerous benefits for businesses, the environment, and society as a whole. By actively addressing and reducing their product carbon footprint, companies can contribute to a more sustainable future while gaining various advantages. Let's explore some of the key benefits of sustainable manufacturing.

Environmental Advantages:

Sustainable manufacturing practices help minimize the negative impact on the environment. By reducing product carbon footprints, businesses can lower greenhouse gas emissions, conserve natural resources, and decrease pollution. This contributes to the preservation of ecosystems, biodiversity, and the overall health of our planet.

Cost Savings and Operational Efficiency:

Adopting sustainable manufacturing practices can lead to significant cost savings in the long run. Energy-efficient technologies, renewable energy sources, and optimized processes can reduce energy consumption and operational costs. Additionally, waste reduction and recycling initiatives can lower waste disposal expenses and provide opportunities for resource recovery and reuse.

Enhanced Brand Reputation and Customer Loyalty:

Consumers today are increasingly conscious of the environmental impact of the products they purchase. By prioritizing sustainable manufacturing and communicating their efforts, businesses can enhance their brand reputation and appeal to environmentally aware consumers. Demonstrating a commitment to reducing product carbon footprints can build trust, loyalty, and positive brand associations.

Regulatory Compliance and Market Access:

Many countries and regions have implemented regulations and standards related to environmental sustainability. By proactively adopting sustainable manufacturing practices and reducing product carbon footprints, businesses can ensure compliance with these requirements. Moreover, sustainable practices can provide access to markets with specific sustainability criteria and preferences.

Innovation and Competitive Advantage:

Embracing sustainable manufacturing often requires innovation and the development of new technologies and processes. By investing in research and development, businesses can drive innovation, improve efficiency, and gain a competitive edge. Sustainable manufacturing practices can differentiate companies in the market, attracting environmentally conscious customers and partners.

In conclusion, sustainable manufacturing offers a range of benefits for businesses, including environmental advantages, cost savings, enhanced brand reputation, regulatory compliance, and innovation. By actively working towards reducing their product carbon footprints, companies can contribute to a more sustainable future while gaining a competitive advantage in the market. Embracing sustainable manufacturing practices is not only a responsible choice but also a strategic decision that can yield long-term benefits for businesses and the environment alike.

>>> Learn more: Reduce Carbon Footprint: Small Changes, Big Impact

Contact us

AirX is the world's first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!