Comparison between plant-based polyethylene and petroleum-based polyethylene

To enhance its influence and raise awareness of its significance, this blog will explore the key differences between plant-based polyethylene and petroleum-based polyethylene. As sustainability becomes an increasingly important consideration, the demand for environmentally friendly materials is on the rise. One such innovation is plant-based polyethylene, derived from renewable plant sources.

To enhance its influence and raise awareness of its significance, this blog will explore the key differences between plant-based polyethylene and petroleum-based polyethylene. As sustainability becomes an increasingly important consideration, the demand for environmentally friendly materials is on the rise. One such innovation is plant-based polyethylene, derived from renewable plant sources.

In this comprehensive comparison, we will examine the production processes, environmental impacts, biodegradability, performance, and properties of both plant-based and petroleum-based polyethylene, introduce one of the leading providers in the industry today. Join us as we unravel the distinct characteristics of these materials and shed light on the future of sustainable plastics. Let's explore the remarkable potential of plant-based polyethylene together.

Introduction

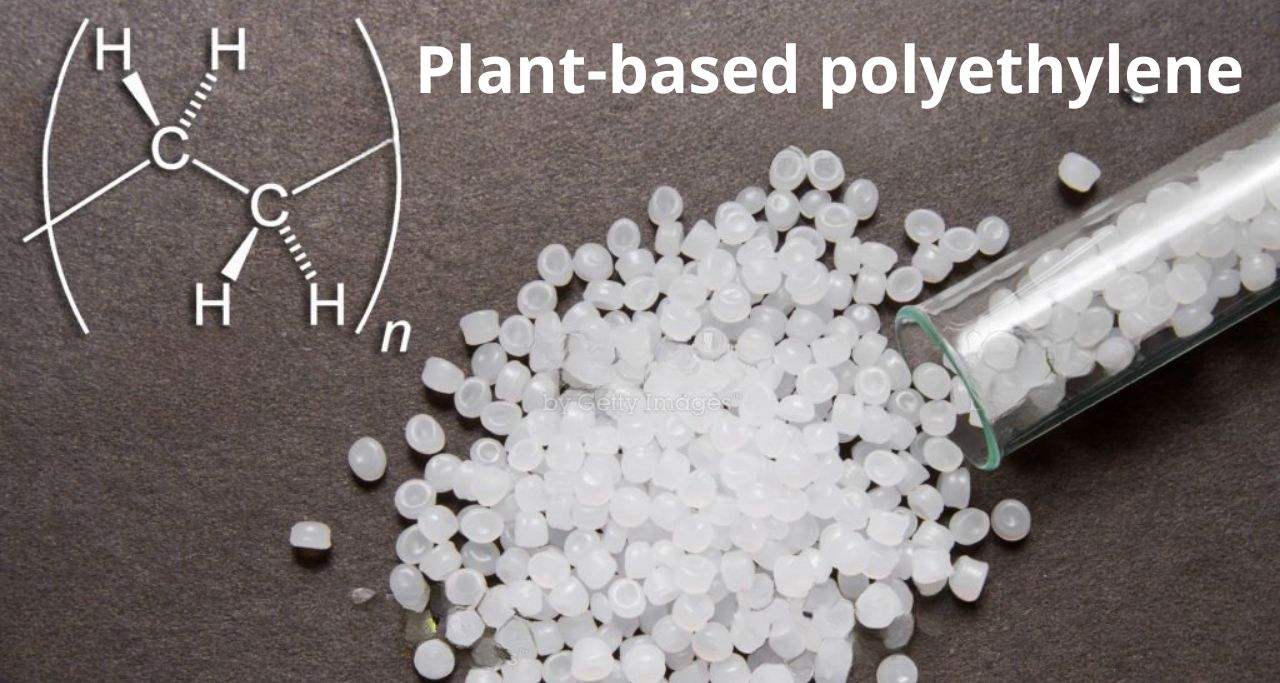

Plant-based polyethylene

Polyethylene derived from renewable plant sources, known as plant-based polyethylene, is gaining significant attention as a sustainable alternative to petroleum-based polyethylene. In this section, we will explore the definition, sources, production process, and environmental impact of plant-based polyethylene.

- Definition and Sources: Plant-based polyethylene is a type of polyethylene produced from renewable plant sources such as sugarcane, corn, or other biomass. The carbon used in its production is captured from the atmosphere through photosynthesis, making it a more sustainable option compared to its petroleum-based counterpart.

- Production Process:The production process of plant-based polyethylene involves several steps. First, the selected plant biomass undergoes a refining process to extract the desired sugars. These sugars are then fermented into ethanol. The ethanol is further converted into ethylene, the building block of polyethylene, through various chemical processes. Finally, the ethylene is polymerized to form plant-based polyethylene.

- Environmental Impact and Sustainability:One of the key advantages of plant-based polyethylene is its reduced carbon footprint. As plants grow, they absorb carbon dioxide from the atmosphere, mitigating greenhouse gas emissions. Therefore, using plant-based sources for polyethylene production can contribute to lowering the carbon emissions associated with plastics. Additionally, plant-based polyethylene has the potential to be biodegradable, further reducing its environmental impact.

The increasing adoption of plant-based polyethylene by industries and consumers showcases the growing demand for eco-friendly materials. Its applications span across multiple sectors, with companies actively integrating plant-based polyethylene into their product portfolios. As we continue to explore the benefits and applications of plant-based polyethylene, it becomes evident that this innovative material has the potential to drive positive environmental change and contribute to a more sustainable future.

Petroleum-based polyethylene

Petroleum-based polyethylene is the most widely used and commercially available form of polyethylene. In this section, we will delve into the definition, sources, production process, environmental impact, and applications of petroleum-based polyethylene.

- Definition and Sources: Petroleum-based polyethylene is derived from fossil fuel sources, primarily crude oil or natural gas. These non-renewable resources serve as the raw materials for the production of polyethylene. The extraction and refining of crude oil or natural gas are crucial steps in obtaining the necessary feedstocks for petroleum-based polyethylene.

- Production Process: The production process of petroleum-based polyethylene involves several stages. First, the crude oil or natural gas is processed to obtain ethylene, the primary building block of polyethylene. Ethylene molecules are then polymerized under controlled conditions, resulting in the formation of long polymer chains, which constitute petroleum-based polyethylene.

- Environmental Impact and Challenges: Petroleum-based polyethylene has significant environmental implications. The extraction, refining, and processing of crude oil and natural gas contribute to carbon emissions and the depletion of fossil fuel resources. Additionally, the disposal of petroleum-based polyethylene products poses challenges, as it is non-biodegradable and can persist in the environment for hundreds of years, contributing to plastic pollution.

Despite its limitations, petroleum-based polyethylene continues to play a crucial role in the global plastics industry due to its wide availability, affordability, and versatility. Efforts are being made to improve the environmental performance of petroleum-based polyethylene through recycling initiatives and advancements in waste management systems.

Comparison of Plant-Based and Petroleum-Based Polyethylene

In this section, we will compare plant-based polyethylene and petroleum-based polyethylene in terms of their environmental sustainability, performance and properties, biodegradability.

Performance and Properties: Both plant-based and petroleum-based polyethylene exhibit similar performance and properties. They share characteristics such as strength, flexibility, and durability, making them suitable for various applications. Plant-based polyethylene can be seamlessly integrated into existing production processes without compromising performance, providing a sustainable alternative without sacrificing quality.

Biodegradability and Disposal Considerations: One notable distinction between plant-based and petroleum-based polyethylene is their biodegradability. While some variants of plant-based polyethylene are biodegradable, petroleum-based polyethylene is non-biodegradable and persists in the environment for extended periods. Biodegradable plant-based polyethylene offers advantages in terms of reducing plastic waste and environmental impact, especially in applications where disposal and end-of-life management are crucial factors.

As the world strives to reduce its carbon footprint and transition to a more sustainable future. By considering the environmental impact, performance, and market dynamics, stakeholders can make informed decisions regarding the use of plant-based and petroleum-based polyethylene.the comparison between plant-based and petroleum-based polyethylene plays a crucial role in shaping responsible choices and driving innovation in the plastics industry.

Leading Provider of Plant-Based Polyethylene: AirX

In this section, we will introduce AirX, a renowned provider in the industry, and highlight their innovations and contributions in the field of plant-based polyethylene.

Introduction to AirX:AirX is a leading provider of plant-based polyethylene and a pioneer in sustainable materials. With a strong commitment to environmental responsibility, AirX has revolutionized the market by offering high-quality, plant-based polyethylene solutions that reduce reliance on fossil fuels and contribute to a circular economy.

Innovations and Contributions: AirX has made significant strides in developing plant-based polyethylene materials with a focus on reducing carbon emissions and plastic waste. Their cutting-edge technology and research have resulted in the creation of biodegradable and compostable polyethylene products that have a minimal environmental impact.

Success Stories and Impact on Sustainability: AirX's innovative plant-based polyethylene solutions have gained recognition and adoption across various industries. Their products have been successfully integrated into applications such as packaging, textiles, and single-use items, offering eco-friendly alternatives that align with sustainability goals. By providing viable alternatives to traditional plastics, AirX is actively contributing to the reduction of plastic pollution and promoting a more sustainable future.

AirX's success not only lies in their product offerings but also in their commitment to transparency and collaboration. They actively engage with partners, customers, and stakeholders to drive positive change and create a more sustainable ecosystem. Some of them include: Uniqlo, Nestle, Paula's Choice, and intercontinental Hotel Groups.

As a leading provider, AirX is setting an example for other companies in the industry, demonstrating that plant-based polyethylene is a viable and effective solution to address the environmental challenges posed by traditional plastics. Their efforts in research, development, and market adoption are instrumental in driving the widespread use of plant-based polyethylene and shaping a more sustainable plastics industry.

Contact us

AirX is the world's first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!