Low-Carbon Footprint plastic

Plastic: it's everywhere we look, from our morning coffee cup to the packaging on our groceries. But what if there was a way to enjoy the convenience of plastic without the environmental guilt? Enter the world of low-carbon footprint plastics!

These innovative materials are revolutionizing the way we think about plastic, offering a sustainable future for our planet. Dive into this blog to explore how low-carbon footprint plastics are changing the game, one eco-friendly product at a time!

Understanding Low-Carbon Footprint Plastics

Traditional plastics have a significant environmental impact, with their production contributing heavily to greenhouse gas emissions. In response to this growing concern, a new generation of materials is emerging: low-carbon footprint plastics. These plastics aim to minimize their environmental impact throughout their entire lifecycle, from raw material extraction to production, use, and disposal.

There are several key approaches to achieving a low carbon footprint in plastics. One strategy focuses on using recycled materials. By incorporating recycled plastic content into new products, manufacturers can significantly reduce the reliance on virgin fossil fuels for plastic production. This approach lowers the overall energy consumption associated with plastic production, leading to a smaller carbon footprint.

Another approach involves utilizing renewable energy sources during the plastic production process. Shifting away from traditional fossil fuels like coal and oil and embracing wind, solar, or hydropower can dramatically reduce greenhouse gas emissions associated with plastic manufacturing.

Finally, advancements in production processes themselves can also contribute to lower-carbon footprint plastics. Optimizing energy efficiency throughout the production chain and implementing innovative technologies can further minimize the environmental impact of plastic production.

It's important to acknowledge that achieving a truly "zero-carbon" plastic is a complex challenge. However, low-carbon footprint plastics represent a significant step forward. These innovative materials offer a more sustainable alternative to traditional plastics, and ongoing research and development efforts hold promise for even greater reductions in their environmental impact.

Benefits of Low-Carbon Footprint Plastics

The environmental benefits of low-carbon footprint plastics are undeniable. The plastic industry is estimated to be responsible for 3-8% of global oil consumption, translating to a significant amount of greenhouse gas emissions. By minimizing the reliance on fossil fuels throughout the lifecycle of plastics, low-carbon footprint options offer a clear environmental advantage.

- Reduced Greenhouse Gas Emissions: This is the most significant environmental benefit. Low-carbon footprint plastics, through approaches like recycled materials and renewable energy sources, can dramatically decrease greenhouse gas emissions associated with plastic production. This translates to a smaller carbon footprint for the entire lifecycle of the plastic product, mitigating climate change.

- Resource Efficiency and Cost Savings: The use of recycled materials promotes resource efficiency, reducing the need to extract virgin resources. Furthermore, advancements in production processes for low-carbon footprint plastics can lead to overall cost savings. In some cases, the use of recycled materials can be more cost-effective than virgin plastic production.

- Market Growth and Economic Opportunities: The growing demand for sustainable solutions is creating new market opportunities for low-carbon footprint plastics. As consumers become more environmentally conscious, companies that embrace these innovative materials can gain a competitive edge. This shift can lead to economic growth within the sustainable plastics sector.

- Social Benefits and Responsible Consumption: The development and adoption of low-carbon footprint plastics can also contribute to social benefits. The transition to a more sustainable plastics industry can create new green jobs focused on recycling, innovation, and production of these eco-friendly materials. Furthermore, the availability of low-carbon footprint options empowers consumers to make responsible choices, promoting a more sustainable future for our planet.

Low-Carbon Footprint Plastics Manufacturer - AirX Carbon

The world's drowning in plastic, but what if the solution wasn't just about using less plastic, but using plastic itself to fight climate change? Here's where AirX Carbon steps in, offering a revolutionary alternative to oil-based plastics with their Low-Carbon Footprint Plastics.

AirX Low-Carbon Footprint Plastics

Harnessing the Power of Plants and Carbon Capture:

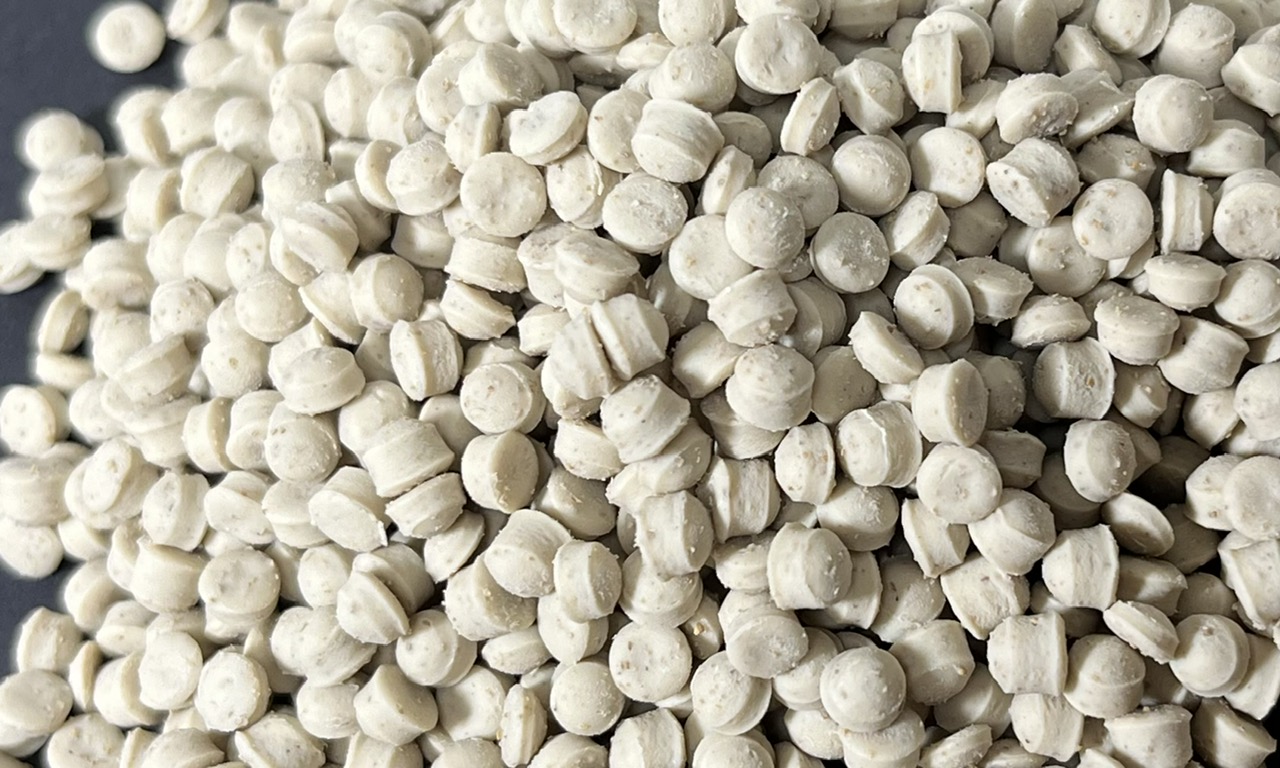

Unlike traditional plastics derived from fossil fuels, AirX’s low-carbon footprint plastics are crafted from renewable, plant-based materials like coffee grounds or rice husk.

Here lies the magic: plants naturally absorb carbon dioxide (CO2) through photosynthesis, a vital process for their growth. When these plant materials are meticulously processed into AirX bioplastics, the captured carbon remains trapped within the final product. This essentially locks away the CO2 for the lifespan of the bioplastic, achieving a negative carbon footprint – a significant leap forward compared to traditional plastics that emit greenhouse gases throughout their lifecycle.

Performance Powerhouse with Sustainability at its Core:

AirX doesn't stop at environmental benefits. Their bioplastics are performance powerhouses, offering mechanical properties comparable to traditional plastics (PP, PE, EVA). This allows for seamless integration into existing production lines, minimizing the need for major infrastructure changes. As a result, AirX bioplastics become a practical and cost-effective solution for manufacturers seeking a more sustainable path through low-carbon footprint plastics.

Carbon Capture Champion: Quantifiable Environmental Impact

AirX's bioplastics capture up to 1.4 kg of CO2 per kg of material produced. This impressive carbon capture capability actively mitigates climate change by sequestering greenhouse gases throughout the product's lifecycle.

Beyond Sustainability: A Commitment to a Circular Economy:

AirX takes a holistic approach to sustainability, demonstrating a deep commitment to responsible resource management. They combine plant-based materials with recycled plastic content, further reducing reliance on virgin resources and promoting a circular economy. Additionally, their bioplastics are recyclable, maintaining compatibility with existing recycling streams. This ensures that AirX products contribute to a closed-loop system, minimizing environmental impact throughout their entire lifecycle.

By championing innovation, performance, and a commitment to a circular economy, AirX Carbon exemplifies the future of low-carbon footprint plastics. Their groundbreaking bioplastics pave the way for a more sustainable future for the plastics industry, offering a compelling combination of environmental responsibility, performance, and cost-effectiveness.

Learn more at:The Carbon Negative Material Market

Contact us

AirX is the world’s first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!