AirX Carbon-Negative Plastic Vs Traditional Plastics

Plastics are ubiquitous in our daily lives, offering convenience and versatility. However, the environmental impact of traditional plastics, with their substantial carbon footprint and contribution to pollution, has raised global concerns. To tackle these challenges, innovative solutions are emerging. One such solution is AirX carbon-negative plastic, a revolutionary alternative that aims to minimize carbon emissions and actively reduce environmental impact. In this comparison, we will explore the differences between AirX carbon-negative plastic and traditional plastics, highlighting its potential to create a more sustainable future.

In this comparison, we will explore the key differences between AirX carbon-negative plastic and traditional plastics, highlighting the significant strides made in creating a more sustainable and eco-friendly material. By examining these two approaches side by side, we can gain a deeper understanding of the transformative potential of carbon-negative plastic and its role in mitigating the environmental impact of plastic consumption.

1. The concept of carbon-negative plastic

Carbon-negative plastic is a type of plastic material that not only reduces its carbon footprint but also actively removes more carbon dioxide from the atmosphere than is emitted during its production and lifecycle. It goes beyond conventional efforts to reduce carbon emissions associated with plastic production and aims to make a net-positive impact on carbon reduction.

The carbon-negative attribute of plastic can be achieved through various methods and technology, such as AirX Carbon-Negative Bioplastics made from coffee grounds. During photosynthesis, plants absorb carbon dioxide and convert it into organic compounds. When coffee grounds are used for plastic production, the carbon captured from the atmosphere remains trapped in the plastic, effectively sequestering carbon dioxide.

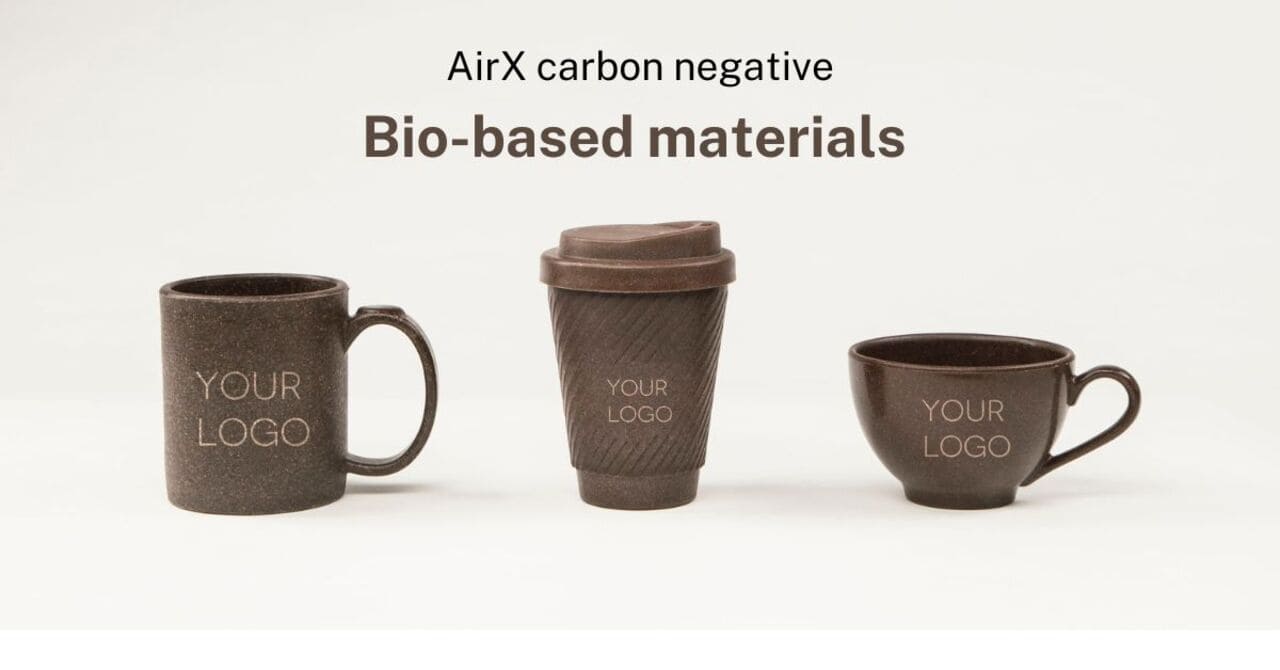

AirX Carbon-Negative Bioplastics are the revolutionary solutions to sustainable environment and economy. Carbon Negative Bioplastics offers to various applications and advantages

2. The production of Carbon-Negative Plastic and Traditional Plastics

Traditional Plastics:

The production process for traditional plastics typically starts with the extraction and refining of fossil fuel-based feedstocks, such as petroleum or natural gas. These feedstocks undergo a series of chemical processes, including polymerization, to create the plastic materials. The production process often involves high energy consumption, emits significant carbon dioxide, and generates other harmful byproducts.

Traditional plastics are commonly produced using non-renewable resources and rely on energy sources that contribute to greenhouse gas emissions, resulting in a substantial carbon footprint.

AirX Carbon-Negative BioPlastics made from Coffee Grounds:

The process begins with the collection of coffee waste from coffee shop chains and processing factories. The waste is then dried to remove moisture and mixed with recycled plastic to act as a binding agent. The resulting mixture is heated and extruded into pellets that can be further processed using common plastic industry technologies like injection molding, extrusion, and blowing film.

By diverting coffee grounds from landfills and utilizing them in the production of polypropylene, reduces the overall volume of waste and promotes sustainable waste management practices. Besides, the Carbon-Negative bioplastics made from coffee grounds can decrease the carbon emissions during the manufacturing compared to the conventional plastics.

>>>Discover more: AirX Remarkable advantages of coffee-based bioplastics

3. Special properties of AirX Carbon-Negative Plastic

- Remarkable durability and strength: surpassing traditional polypropylene materials. These properties can be applied in various industries.

- Excellent heat resistance and insulation properties: suitable for use in demanding environments like the automotive and packaging industries

- Impressive chemical resistance: resists solvents and acids, offering practical benefits and ensuring longevity in challenging environments

AirX, purchasing the purpose of providing high-quality plant-based carbon negative products, always searching and innovating the technique of bio-based products manufacturing. Our process and materials are ensured to be closely monitored, which adapt the needs of qualified finished products of our customers. Our bio-based materials, especially Coffee based polypropylene offer the same functions of conventional plastics, but it's environmentally friendly characteristics make them an ideal choice for partners, businesses looking for sustainable development.

AirX Coffee-based polypropylene possesses a remarkable advantage as they undergo decomposition within 12 months of use. Subsequently, they are collected and brought back to the factory for mechanical recycling, where they are shredded and recycled into a completely new product. This approach contributes to promoting the product's life cycle and establishes a closed-loop system for its utilization.

Contact us

AirX is the world’s first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!