Industry Solutions: Carbon Capture Materials for Meeting CSR Commitment

Introduction

What is Carbon Capture?

Carbon capture materials are substances used to trap carbon dioxide (CO2) from gases. They come in various types, like solid sorbents, liquid sorbents, and membranes. Solid sorbents, such as metal-organic frameworks, adsorb CO2 from gas streams. Liquid sorbents, like amines, soak up CO2 and can be heated to release it. Membranes are barriers that let CO2 through while blocking other gases. Solid adsorbents capture CO2 physically. Researchers are working on improving these materials to help reduce CO2 emissions and fight climate change.

Corporate Social Responsibility (CSR) Commitment

Corporate Social Responsibility (CSR) commitment refers to a company's voluntary initiative to integrate social, environmental, and ethical concerns into its business operations and interactions with stakeholders. It means that businesses take on responsibilities beyond profit-making and actively work to have a positive impact on society and the environment. CSR includes actions such as philanthropy, ethical sourcing, reducing environmental impact, supporting local communities, and ensuring fair labor practices.

Why is it Important for Businesses?

CSR is important for businesses for several reasons:

Reputation and Brand Image: Engaging in CSR initiatives enhances a company's reputation and brand image. This makes them more attractive to customers, investors, and employees.

Competitive Advantage: CSR can provide a competitive edge. This can be achieved by distinguishing the business from competitors. Thus, attracting more stakeholders.

Risk Mitigation: CSR helps mitigate legal, regulatory, and environmental risks. This could help prevent negative publicity and legal challenges.

Cost Savings: Sustainable practices can lead to cost savings by reducing energy consumption, waste, and resource usage. Which in turn improves operational efficiency.

Access to Capital: Companies with strong CSR commitments may find it easier to secure financing and investment. Because investors increasingly consider environmental and social performance.

Carbon Capture Technologies

Several carbon capture technologies are available, each with its mechanisms and applications. Here's an overview of some of the key carbon capture methods:

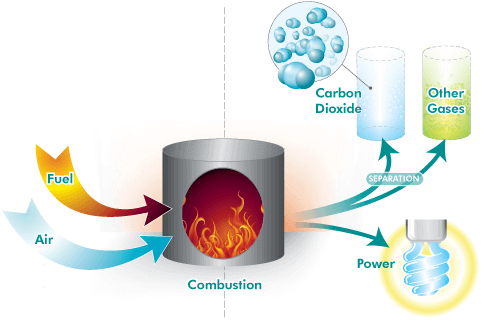

Post-combustion Capture:

Mechanism: Post-combustion capture occurs after the combustion of fuels, where CO2 is captured from the flue gases. Flue gases are produced in industrial and thermal power plants.

Applications: Suitable for retrofitting existing industrial and power plants to reduce CO2 emissions. It is a key technology in BECCS when coupled with biomass.

Oxy-Fuel Capture:

Mechanism: Oxy-fuel combustion involves burning fuel in a high-purity oxygen (O2) environment to produce flue gases with concentrated CO2. Then can it be captured?

Applications: Used in power plants to generate flue gases rich in CO2. Which makes it an option for BECCS when biomass is involved.

Precombustion Capture:

Mechanism: Precombustion capture takes place before the combustion of fuel, typically converting hydrocarbons into hydrogen (H2) and CO2. CO2 is captured from the hydrogen-rich gas stream.

Applications: Often used in integrated gasification combined cycle (IGCC) power plants and hydrogen production, it can be integrated into BECCS.

Sustainable Materials for Carbon Capture

Various materials and technologies are employed for carbon capture. They each have their sustainability aspects. Here's an exploration of some of these materials and technologies, along with their sustainability considerations:

Absorbents (Liquid Sorbents):

Mechanism: Absorbents, typically liquid sorbents like amines, absorb CO2 from gas streams, forming soluble compounds that can be separated.

Sustainability Aspects: Sustainability concerns for liquid sorbents involve several factors. These factors include the energy needed for solvent regeneration, the potential toxicity of chemicals used, and the disposal of waste. To enhance sustainability, it's vital to work on developing environmentally friendly and less energy-consuming solvents, as well as efficient regeneration processes.

Adsorbents (Solid Sorbents):

Mechanism: Adsorbents are solid materials (e.g., activated carbon, metal-organic frameworks) that capture CO2 through physical adsorption.

Sustainability Aspects: Sustainability challenges include the energy needed for regeneration, the potential use of non-renewable materials, and the environmental impact of adsorbent production. Sustainable adsorbents and regeneration processes are under research to reduce these impacts.

Membrane Separation:

Mechanism: Membrane technologies use selective barriers to separate CO2 from gas streams based on differences in permeability.

Sustainability Aspects: Sustainability concerns involve membrane material production, maintenance, and end-of-life disposal. Developing eco-friendly and durable membrane materials and efficient processes is vital.

Chemical Looping Combustion:

Mechanism: Chemical looping combustion uses metal-based oxygen carriers. They help fuel combustion and capture CO2.

Sustainability Aspects: Sustainability aspects include the selection of metal carriers, their availability, and the environmental impact of metal mining and recycling. The research aims to identify more sustainable metal carriers and recycling methods.

Direct Air Capture (DAC):

Mechanism: DAC technology captures CO2 directly from the ambient air.

Sustainability Aspects: Key sustainability issues include the energy intensity of DAC systems and the choice of sorbents or chemicals used. Developing energy-efficient DAC processes and sustainable sorbents is a focus.

Industry Case Studies

Several real-world examples of companies and industries that have successfully implemented carbon capture materials to meet their CSR commitments, with positive environmental and social impact:

Climeworks: A Swiss company that developed direct air capture technology to remove carbon dioxide from the atmosphere. They have partnered with companies like Shopify, Porsche, and Stripe to offset carbon emissions. This shows their commitment to environmental responsibility.

Carbon Engineering: A Canadian company specializing in capturing carbon dioxide from industrial flue gases and converting it into fuels and other products. Their collaborations with oil and gas companies, such as Occidental Petroleum and Storegga, show how the industry can align with sustainability goals.

Global Thermostat: A US-based company with technology for capturing carbon dioxide from the atmosphere through electrochemical capture. Their partnerships with utilities and industrial companies are a clear illustration of the positive environmental and social impact of their technology.

Mitsubishi Heavy Industries: A Japanese engineering company that has developed carbon capture technology that uses solvents. They have worked with power companies like JERA and Kansai Electric Power Company. Thus, contributing to emissions reduction at power plants.

BASF: A German chemical company that employs a special membrane to capture carbon dioxide from flue gases. Collaborations with industrial companies like Shell and Linde show the potential for scaling up carbon capture efforts.

Challenges and Future Prospects

Challenges

High Cost: The high cost of carbon capture technologies has been a significant challenge. Companies and industries often face large expenses related to materials, equipment, and energy required for the capture process.

Example: In the case of the Petra Nova project in Texas, they were successful at capturing CO2 from a coal-fired power plant. However, the high implementation costs led to the temporary suspension of the project.

Low Efficiency: Carbon capture technologies are not yet highly efficient at capturing CO2. Inefficiencies can result in a significant amount of CO2 escaping the capture process. This could reduce its overall effectiveness.

Example: The Boundary Dam Carbon Capture Project in Canada faced operational issues and didn't achieve its target capture rate initially. This affected their efficiency.

Limited Capacity: The availability of storage capacity for captured CO2 is limited. This necessitates the transportation of captured CO2 over long distances to storage sites. Which adds complexity and cost to the process.

Public Perception: Some members of the public have concerns about the safety and environmental impact of carbon capture technologies. This can hinder their acceptance.

Example: The controversy around the Sleipner project in Norway, one of the earliest carbon capture initiatives, raised concerns about the potential environmental impact of underground CO2 storage.

Potential Future Developments:

New Materials: Ongoing research aims to develop new materials with higher CO2 capture capacity and lower energy requirements. These materials could enhance the efficiency and cost-effectiveness of carbon capture.

Example: Researchers are working on advanced materials such as metal-organic frameworks (MOFs) and amino acids-based solutions. This has shown promise in improving capture capacity.

New Capture Processes: The development of more efficient and energy-saving capture processes is in progress. This could make carbon capture more scalable and environmentally friendly.

Example: Innovative processes like chemical looping, cryogenic CO2 separation, and enzymatic capture are being explored for their potential to improve efficiency.

New Storage Technologies: Research is focused on creating advanced storage technologies to increase the storage capacity available for captured CO2. Thus, simplifying storage and reducing the need for long-distance transportation.

Example: Enhanced Oil Recovery (EOR) is a storage method that repurposes captured CO2 to extract more oil from depleted wells, increasing storage capacity and offering economic benefits.

If You Want To Know More About Other Eco-Friendly Materials:

- Leading the Charge: How Carbon-Negative Brands are Transforming Industries

- Unveiling Carbon-Negative Companies

- Biodegradable Plastics: The Eco-Friendly Solution You've Been Waiting For

Contact us

AirX is the world’s first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

Whatsapp: +84 969 742 950

Email: [email protected]

We look forward to hearing from you!

(or resource)

(or resource)