Bioplastic Compostable: The Next Generation of Green Material for a Circular Economy

In our quest for sustainable solutions, the need for eco-friendly materials has become increasingly vital. As the negative environmental impact of traditional plastics continues to be a growing concern, the demand for alternatives that align with the principles of a circular economy is on the rise.

Bioplastic compostable has emerged as a promising solution, offering a green material that not only reduces waste but also contributes to the creation of a more sustainable future.

Importance of green materials for a circular economy

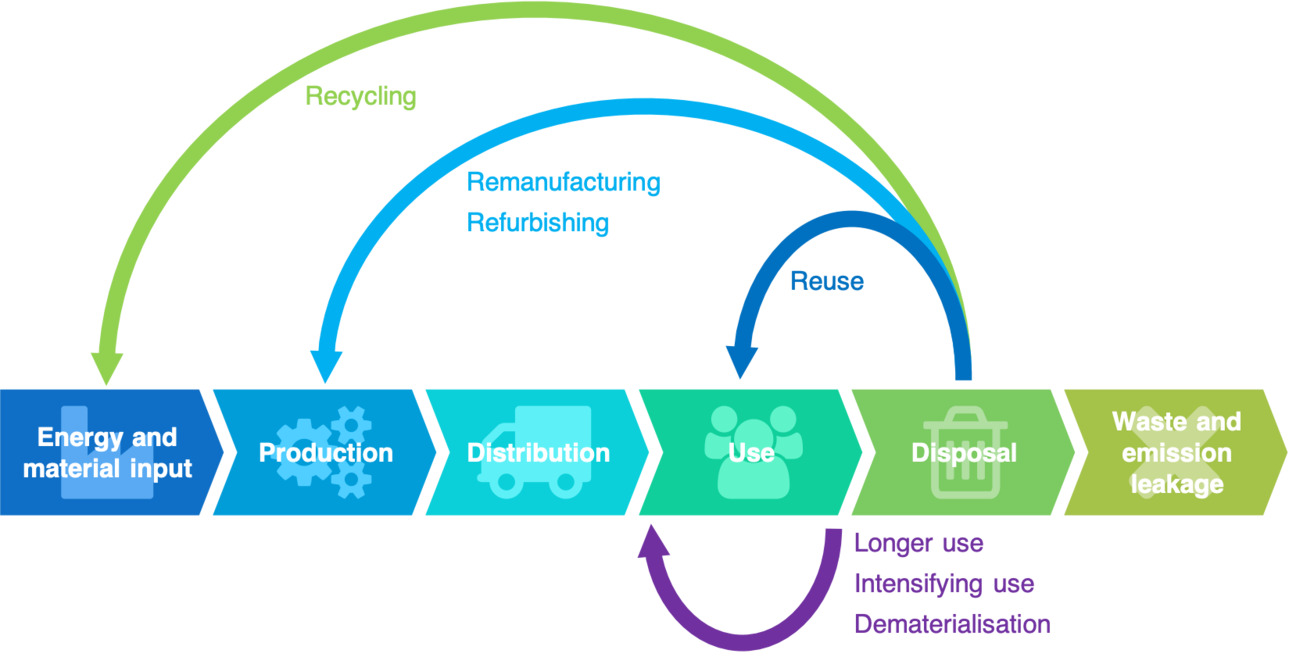

Green materials play a crucial role in driving the transition towards a circular economy. A circular economy aims to minimize resource consumption, waste generation, and environmental impact by promoting the efficient use and reuse of materials throughout their lifecycle. Embracing green materials is not only vital for environmental preservation but also presents economic, social, and health benefits that contribute to a more resilient and prosperous future.

The Next Generation of Green Material: Bioplastic compostable

Definition

Bioplastic compostable is a type of material derived from renewable sources such as plant-based materials, including corn starch, sugarcane, or cellulose and even coffee grounds. Unlike conventional plastics, bioplastic compostable is designed to break down completely and safely within a composting environment. This means that it can return to the earth, nourishing the soil and completing the natural cycle.

Bioplastic compostable possesses similar characteristics to traditional plastics, including durability, flexibility, and resistance to heat and moisture. However, it distinguishes itself through its ability to decompose in a composting facility within a specific timeframe, typically ranging from a few weeks to a few months. This unique feature makes bioplastic compostable an ideal choice for a range of applications, including packaging materials, food service products, and consumer goods.

Properties

Bioplastic compostable materials possess unique properties that make them suitable for sustainable packaging and other applications.

Here are some key properties of bioplastic compostable:

- Biodegradability: One of the primary properties of bioplastic compostable is its ability to break down naturally and return to the environment. Bioplastic compostable materials are designed to undergo biological decomposition through the action of microorganisms in a composting environment. This property ensures that the materials do not persist in the environment, reducing waste accumulation and pollution.

- Compostability: These materials are designed to be compostable, meaning they can undergo controlled degradation in composting facilities. Composting allows for the conversion of bioplastic waste into nutrient-rich compost, which can be used to enhance soil quality and support plant growth.

- Renewable Source: Bioplastic compostable materials are derived from renewable resources such as plant-based feedstocks. These resources can be regrown or replenished, reducing reliance on finite fossil fuel-based resources. By utilizing renewable sources, bioplastic compostable materials contribute to reducing carbon emissions and promoting sustainability.

- Reduced Carbon Footprint: Our materials typically have a lower carbon footprint compared to conventional plastics. The production of bioplastic compostable materials often requires less energy and generates fewer greenhouse gas emissions during manufacturing. Additionally, the use of renewable feedstocks contributes to carbon sequestration as plants absorb carbon dioxide during growth.

- Versatility: They can be engineered to have a range of characteristics such as flexibility, strength, and barrier properties, making them suitable for various applications. Bioplastic compostable materials can be used in packaging, food service products, agricultural films, and other disposable items.

- Safety and Non-Toxicity: Bioplastic compostable materials are designed to be safe for use with food and other sensitive applications. They are formulated to meet strict regulations and standards for contact with food and beverages, ensuring that they do not release harmful substances into the environment or contaminate the products they come into contact with.

Eco-friendly products are more safety and non-toxic than other products made from traditional plastics.

The properties of our eco-friendly materials make them a promising solution for reducing the environmental impact of traditional plastics. By embracing these properties, we can move towards a more sustainable and circular economy for business.

Sources and production

The production of bioplastic compostable involves the use of renewable resources and follows specific manufacturing processes to create a sustainable and environmentally friendly material:

- Renewable Feedstock: Bioplastic compostable is derived from renewable sources such as plant-based materials. Common feedstocks include corn starch, sugarcane, cellulose, and coffee grounds.

- Polymerization: Polymerization is a key step in bioplastic production. The extracted or synthesized monomers are subjected to polymerization processes, such as melt extrusion or chemical reactions, to form long polymer chains. These chains are then processed into the desired bioplastic compostable material, which can be in the form of pellets, sheets, films, or other shapes.

- Additives and Blending: To enhance the performance and functionality of bioplastic compostable, additives may be incorporated during the production process. These additives can improve properties such as strength, flexibility, heat resistance, and barrier properties. Blending different types of bioplastics or combining them with traditional plastics can also result in customized materials with specific characteristics.

- Processing Techniques: Our compostable materials can be processed using various techniques depending on the desired end product. These techniques include extrusion, injection molding, blow molding, thermoforming, and film casting. The processing method determines the shape, size, and final properties of the bioplastic compostable products.

It is important to note that specific production methods may vary depending on the type of bioplastic and the manufacturer. However, the overall goal remains the same: to create a bioplastic compostable material that offers sustainable and environmentally friendly alternatives to traditional plastics.

The way bioplastic compostable becomes a helpful material for business

Bioplastic compostable materials not only offer environmental benefits but also provide numerous advantages for businesses. Bioplastic compostable materials offer various advantages for businesses, including meeting consumer demand, differentiation, brand image enhancement, compliance with regulations, cost-effectiveness, resource efficiency, innovation, market opportunities, and positive public relations.

One of bioplastics that can help businesses achieve a carbon circular economy is biocomposite with coffee grounds as a component: Coffee Biocomposite from AirX - the world's first producer and trader of coffee bio-composite in Vietnam.

The AirX material can properly becomes a helpful raw material for business on the way to circular economy following these characteristics: Carbon negative, End-of-life option when they can biodegrade into water, CO2, and biomass within just 12 months, limit the demand for new plastic production with coffee grounds and recycled plastics.

>>>> Learn more at: The Success Story of the Bio Plastics Company

Contact us

AirX is the world's first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!