The Rise of Bio Polyethylene Resin: Green solutions

Polyethylene (PE) resin has long been a widely used material for manufacturing various plastic products that we encounter in our daily lives. However, the prevalence of traditional PE resin has also contributed significantly to the pollution of our environment. The non-biodegradable nature of conventional PE poses a significant challenge in waste management and has detrimental effects on ecosystems.

To address this issue, bio polyethylene resin (Bio-PE) has emerged as a promising solution. Bio Polyethylene is derived from renewable resources, such as sugarcane or corn, and offers a more sustainable alternative to conventional PE resin. By embracing Bio-PE, we can mitigate the environmental impact associated with plastic waste and pave the way for a healthier and greener future.

The development of Bio Polyethylene Resin

Over the years, humans have explored plastics since the 19th century as the materials of choice, have various functional properties, even if it is mechanical, thermal or acoustic.

Through this discovery, people have witnessed the tremendous development of plastic, making it an irreplaceable material to this day. And Polyethylene is the one of the most common resin that makes up the plastics.

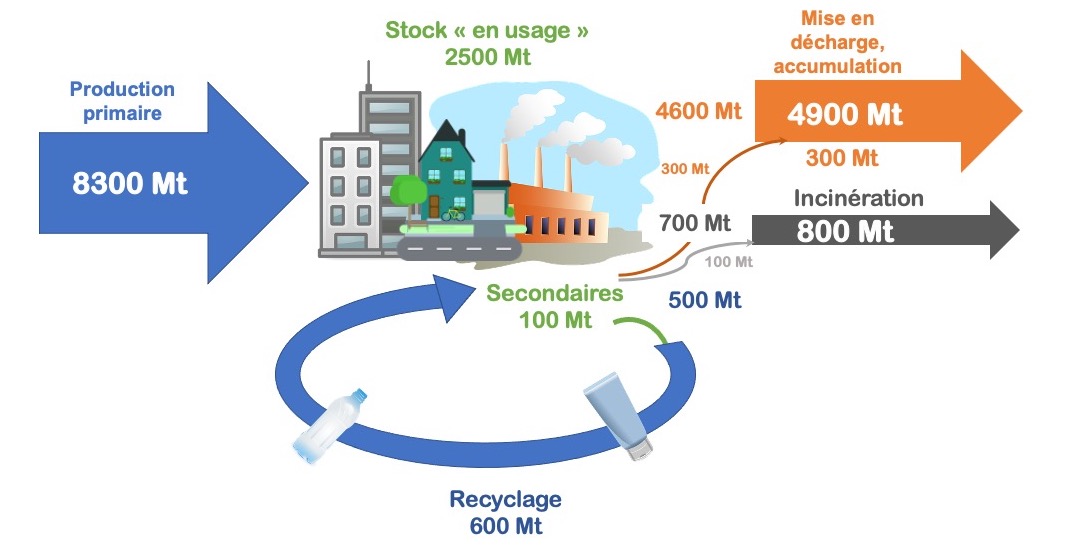

The end of use plastics have been landfilling and/or treatment, however; are still found in ecosystems; older plastics, not often biodegradable, would take several decades or centuries to degrade.

Illustration of the fate of plastics since their industrial mass production in the 1950s.

Faced with the facts and figures relevant with the harmful effects of plastics and given the growing consumer demand for more environmentally friendly products, research has been directed since the 2000s towards the design of plastic materials produced from renewable plant materials, as substitutes for fossil inputs including oil.

Bio Polyethylene Resin is one of the biobased choice for this solution.

What is Bio Polyethylene Resin?

Bio polyethylene resin, also known as bio-based polyethylene, is a type of polyethylene that is partly derived from renewable resources such as sugarcane, corn, or other biomass feedstocks.

At AirX, the world’s first carbon-negative bio-material made from coffee grounds manufacturer, the process of coffee-based polyethylene begins with the collection of coffee waste from coffee shop chains and processing factories. The waste is then dried to remove moisture and mixed with recycled plastic to act as a binding agent. The resulting mixture is heated and extruded into pellets that can be further processed using common plastic industry technologies like injection molding, extrusion, and blowing film.

The resulting resin shares similar properties with traditional polyethylene, such as flexibility, durability, and resistance to moisture and chemicals.

AirX, purchasing the purpose of providing high-quality plant-based carbon negative products, always searching and innovating the technique of bio-based products manufacturing. Our process and materials are ensured to be closely monitored, which adapt the needs of qualified finished products of our customers. Our bio-based materials offer the same functions of conventional plastics, but its environmentally friendly characteristics make them an ideal choice for partners, businesses looking for sustainable development.

Applications of Bio Polyethylene Resin

Packaging industry: According to a report by Grand View Research, the global biodegradable packaging market is projected to reach USD 24.67 billion by 2025, driven by the increasing demand for eco-friendly packaging solutions. Bio polyethylene resin gained significant traction in the packaging industry, used in the production of various packaging materials, including films, bottles, and containers.

Agricultural applications: Mulch films, greenhouse films Bio polyethylene resin is widely utilized in agricultural applications. These films help enhance crop growth, conserve soil moisture, and control weeds. The global agricultural films market, including biodegradable films, is expected to grow significantly.

Automotive industry: The automotive industry is also incorporating bio polyethylene resin in various applications such as door panels, trims, and seat cushions. Additionally, bio polyethylene resin's lightweight properties help to improved fuel efficiency and reduced emissions.

According to a report by Marketsand Markets, the global automotive plastics market is projected to reach USD 59.7 billion by 2026, with a growing demand for sustainable and lightweight materials. Bio polyethylene resin is expected to contribute to this market growth.

Consumer goods: Textiles, bags, toys Bio polyethylene resin finds application in the production of consumer goods such as textiles, bags, and toys. The use of bio polyethylene resin in manufacturing these goods aligns with the growing market trend. According to a report by Statista, the global sustainable textiles market is projected to reach USD 150 billion by 2025. Bio polyethylene resin contributes to this market by providing a sustainable material option for textile production.

Learn more: Introducing Biobased Polyethylene: 5 Fascinating Facts

Contact us

AirX is the world’s first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!