What benefits can bio-composite made from starch provide?

From our previous blog post, we gained a basic understanding of bio-composites. In this article, we will explore "What benefits can bio-composites made from starch provide?" and delve into the myriad advantages of bio-composite made from starch.

These sustainable materials, known as bio-composites, originate from starch and offer remarkable benefits across various industries. From automotive manufacturing to packaging solutions, these bio-composites provide environmentally friendly alternatives with exceptional properties. Join us as we delve deeper into the astounding potential and superior benefits of bio-composite made from starch.

The benefits in automotive component manufacturing include

Weight Reduction: bio-composite made from starch are typically lighter in weight compared to traditional materials like metals. This lightweight nature can reduce the weight of automotive components such as body panels, dashboards, or interiors. Weight reduction improves fuel efficiency, reduces carbon emissions, enhances vehicle performance, and increases safety.

Mechanical Strength and Flexibility: Bio-composites made from starch can enhance the mechanical properties of automotive components. The incorporation of reinforcements like natural or synthetic fibers in the bio-composite helps increase stiffness, durability, and impact resistance of the material. Additionally, bio-composite made from starch exhibit good flexibility, minimizing damage under load and impact.

Easy Processing and Recycling: bio-composite made from starch are relatively easy to process. They can be molded or processed using modern manufacturing techniques. This facilitates efficient production of automotive parts from bio-composites, saving time and resources. Moreover, bio-composite made from starch have high recyclability, reducing waste and promoting sustainability in the automotive industry.

From the above benefits, using bio-composite made from starch in automotive component manufacturing offers benefits in weight reduction, improved mechanical strength and flexibility, as well as ease of processing and recycling. These advantages not only contribute to the performance and safety of vehicles but also contribute to environmental sustainability and reduced carbon emissions in the automotive industry.

Several advantages in the packaging revolution

Sustainable Packaging Solution: The use of bio-composites made from starch addresses the growing demand for sustainable packaging materials. As consumers and businesses become more environmentally conscious, there is a need for packaging solutions that minimize environmental impact. bio-composite made from starch are renewable, biodegradable, and compostable, providing a viable alternative to conventional plastic packaging. They help reduce dependence on fossil fuels, minimize plastic waste, and contribute to a circular economy.

Enhanced Product Protection: Bio-composites made from starch can be engineered to possess excellent barrier properties. By incorporating additives or coatings, these materials can provide effective moisture resistance, oxygen barrier, and UV protection. These properties help preserve the freshness, quality, and shelf life of packaged goods, extending their usability. Whether it's food, cosmetics, or pharmaceuticals, bio-composite made from starch offer reliable protection against external factors that can compromise product integrity.

Brand Differentiation and Consumer Appeal: As sustainability becomes a significant factor in consumer purchasing decisions, businesses can leverage bio-composite made from starch to differentiate their brands and attract environmentally conscious consumers. Using eco-friendly packaging materials demonstrates a commitment to sustainability and aligns with consumer values. Bio-composites made from starch can enhance brand reputation, foster customer loyalty, and contribute to a positive brand image associated with environmental responsibility.

Regulatory Compliance: With increasing regulations and bans on single-use plastics, bio-composites made from starch offer a compliant solution for packaging. They meet requirements for eco-labels, certifications, and regulations related to compostability and biodegradability. Businesses can confidently adopt bio-composite made from starch knowing that they align with evolving environmental regulations and contribute to waste reduction targets.

Innovations and Customization: bio-composite made from starch provide opportunities for innovation and customization in packaging design. They can be molded into various shapes and sizes, offering flexibility in creating unique packaging solutions. These materials can be compatible with existing manufacturing processes, making them easily adaptable for packaging production lines.

Overall, bio-composites made from starch offer a revolutionary approach to packaging by providing sustainable alternatives, enhanced product protection, brand differentiation, compliance with regulations, and opportunities for innovation. By embracing bio-composite made from starch, the packaging industry can drive the shift towards a more sustainable and environmentally friendly future.

Several notable applications of bio-composite made from starch

Construction and Building Industry: Bio-composite materials are increasingly being used in construction and building projects. They offer excellent structural integrity, durability, and insulation properties. These materials are utilized in the production of panels, beams, and boards, contributing to energy-efficient and eco-friendly buildings.

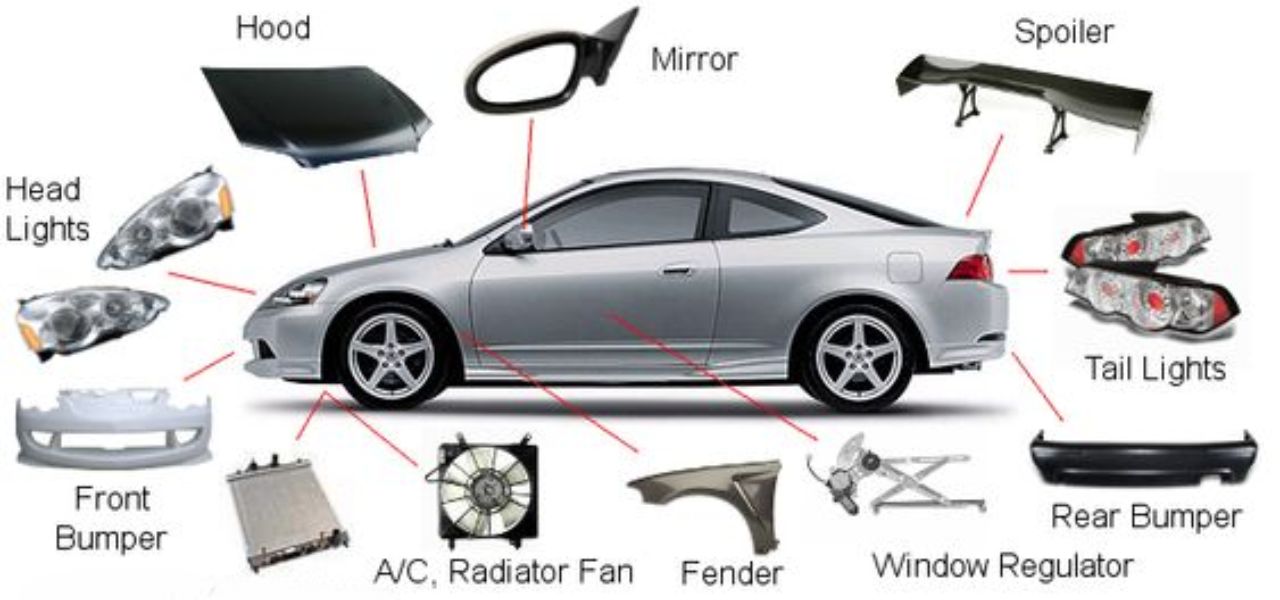

Automotive Sector: The automotive industry is embracing the use of bio-composites for manufacturing lightweight and sustainable components. Bio-composite materials are employed in interior panels, door panels, seat backs, and various other non-structural parts. Their strength-to-weight ratio, noise reduction properties, and eco-friendliness make them an ideal choice for enhancing fuel efficiency and reducing the environmental impact of vehicles.

Packaging Solutions: Bio-composite materials have gained traction in the packaging industry. They are utilized in the production of biodegradable and compostable packaging materials, such as trays, containers, and films. These materials provide a viable alternative to traditional plastic packaging, helping to reduce waste and promote a circular economy.

Consumer Goods and Furniture: Bio-composite materials are also finding applications in the production of consumer goods and furniture. They are used to create sustainable and aesthetically pleasing products, including furniture, household items, and decorative pieces. These materials offer a balance between durability, design flexibility, and environmental consciousness.

The versatile applications of bio-composite materials highlight their immense potential for creating a more sustainable future across diverse sectors. As research and development efforts continue, we can expect to witness further advancements and an expanded range of applications for these eco-friendly materials.

These are just a few examples of the diverse applications of bio-composites made from starch. Ongoing research and development continue to explore new possibilities for utilizing these sustainable materials across various industries.

Contacts

AirX is the world's first carbon-negative bio-material made from coffee grounds manufacturer.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!