Banana Peel Bioplastic - A New Breakthrough

Banana peel bioplastic is a new and exciting development in the world of sustainable materials. It is made from the discarded peels of bananas, which are typically seen as waste. This innovative material has a wide range of applications, from packaging to 3D printing. Banana peel bioplastic has several benefits over traditional plastics, including being biodegradable and compostable, as well as being made from a renewable resource.

In this blog, we will explore the benefits of banana peel bioplastic and how it can be used as a sustainable alternative to traditional plastics.

What is banana peel bioplastic?

Banana peel bioplastic is a new and exciting development in the world of bioplastics. Bioplastics are becoming increasingly popular as an eco-friendly alternative to traditional plastics, which can take hundreds of years to decompose and cause environmental damage. Banana peel bioplastic is made from discarded banana peels, which are an abundant and readily available source of starch.

The concept of bioplastics is not new, but their popularity is growing as people become more aware of the environmental impact of traditional plastics.

Using banana peels as a source of bioplastic has several benefits. First, banana peels are an abundant resource that would otherwise go to waste. Second, the process of turning banana peels into bioplastic requires minimal energy and resources. Finally, banana peels are composed of a high amount of starch, making them an ideal source for bioplastic production.

Banana peel bioplastic has several applications, including packaging, disposable cutlery, and other single-use items. In addition to being biodegradable, it is also compostable, meaning it can be broken down and used as a nutrient-rich soil amendment.

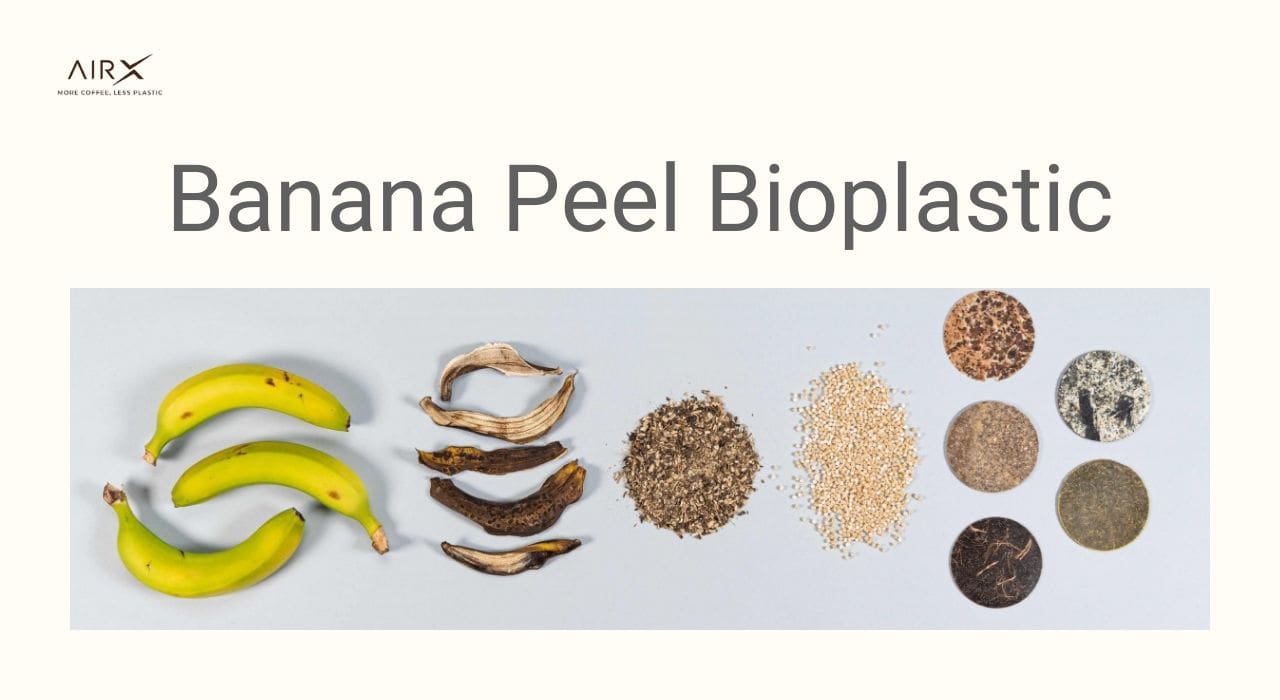

The production of banana peel bioplastic is a simple process. The peels are first dried and ground into a fine powder. The powder is then mixed with a plasticizer, such as glycerol or vinegar, and heated to create a malleable material. The material can then be molded into various shapes and forms, depending on the desired application.

Overall, banana peel bioplastic is an exciting new development in the world of bioplastics. Its use has the potential to reduce waste, decrease reliance on traditional plastics, and promote sustainable practices. As the popularity of bioplastics continues to grow, we will likely see more innovative solutions like this bioplastic emerge.

How banana peel bioplastic is produced

Banana peel bioplastic is an innovative solution to the growing plastic pollution crisis. It is a type of bioplastic that is made from discarded banana peels, which are abundant in tropical countries. Here is a look at how it is produced.

The first step in producing banana peel bioplastic is to collect banana peels that would otherwise go to waste. The peels are washed thoroughly to remove any dirt or debris. They are then dried and ground into a fine powder using a grinder.

Next, the powdered banana peels are mixed with a natural plasticizer, such as glycerol or sorbitol, to make a paste-like substance. The plasticizer helps to give the bioplastic its flexibility and durability.

Once the paste has been mixed thoroughly, it is poured into a mold and left to dry. The drying process can take several hours, depending on the size and shape of the mold. Once the bioplastic has hardened, it can be removed from the mold and used for a variety of purposes, such as packaging or single-use items like cutlery and straws.

The production process for banana peel bioplastic is relatively simple and inexpensive compared to traditional plastic manufacturing methods. It also has a lower environmental impact since it uses waste materials as its primary ingredient, reducing the amount of agricultural waste that goes into landfills.

Moreover, banana peel bioplastic has the potential to be a game-changer for countries that rely heavily on banana cultivation. These countries can now turn their waste into a valuable resource and generate income by selling the bioplastic products they produce.

In conclusion, banana peel bioplastic is a promising breakthrough in the field of sustainable materials. Its production process is simple, inexpensive, and has a low environmental impact. The use of waste materials also means that it has the potential to be a valuable resource for countries that rely on banana cultivation. It is an excellent example of how innovative solutions can help address the global plastic pollution crisis.

Benefits of banana peel bioplastic

Banana peel bioplastic is a new sustainable material that has the potential to revolutionize the world of packaging. Made from discarded banana peels, this bioplastic is not only eco-friendly but also offers several benefits over traditional plastics. In this section, we will explore some of the key benefits of this bioplastic.

- Eco-Friendly:

One of the main benefits of banana peel bioplastic is that it is made from a renewable resource that would otherwise go to waste. By using banana peels to make bioplastic, we can reduce our dependence on non-renewable resources and help prevent environmental pollution caused by plastic waste.

- Biodegradable:

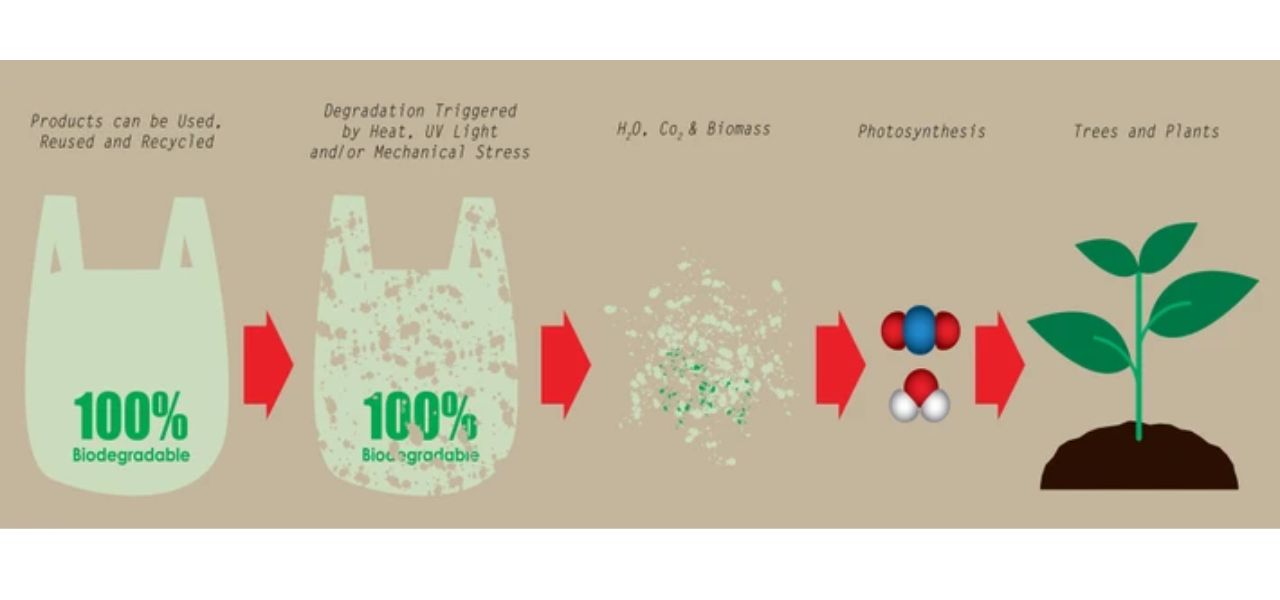

Unlike traditional plastics that take hundreds of years to decompose, banana peel bioplastic is biodegradable. This means that it will break down naturally into organic matter without harming the environment. This is a crucial benefit, as it means that it can help reduce the amount of plastic waste in landfills and oceans.

- Versatile:

Banana peel bioplastic is a versatile material that can be used to make a variety of products, including packaging, cutlery, and even clothing. This makes it an attractive alternative to traditional plastics, which are limited in their applications.

- Cost-Effective:

Banana peel bioplastic is also cost-effective to produce, as it uses readily available waste material as its primary ingredient. This means that it has the potential to be produced on a large scale at a relatively low cost.

- Renewable:

Banana peel bioplastic is made from a renewable resource, which means that it can be produced indefinitely without depleting the planet's natural resources. This is a crucial benefit in a world where the demand for plastic is constantly increasing, and non-renewable resources are becoming scarcer.

In conclusion, banana peel bioplastic is a promising new material that offers several benefits over traditional plastics. From its eco-friendliness and biodegradability to its versatility and cost-effectiveness, this bioplastic has the potential to change the way we think about packaging and other plastic products. As research into this material continues, we can expect to see even more innovative applications for it in the future.

>>> Learn more: Bioplastic Companies Paving the Way to a Sustainable Future

Contact us

AirX is the world's first carbon-negative bio-material made from coffee grounds.

We specialize in producing bio-based composites using recycled carbohydrates derived from by-products such as coffee grounds, coconut husk, husk, and bamboo. Our goal is to promote sustainability through the use of eco-friendly materials.

We are always here to help and provide the best service possible. If you have any questions or would like to receive advice and feedback directly from our sales staff, please do not hesitate to contact us. You can reach us through:

- Whatsapp: +84 969 742 950

- Email: [email protected]

We look forward to hearing from you!